DEFOLIATION IN COTTON: USE A ‘TEAM’ APPROACH FOR OPTIMAL APPLICATIONS

PhytoGen explains how the TEAM approach to cotton defoliation — Timing, Environment, Application and Materials — delivers effective, efficient results

PhytoGen explains how the TEAM approach to cotton defoliation — Timing, Environment, Application and Materials — delivers effective, efficient results

Cotton defoliation is as much an art as a science. It involves a visual analysis of the crop and knowledge of the defoliation process, summarized by the acronym TEAM: timing, environment, application and materials. Using judgment based on scouting and experience, growers can apply the best practices for cotton defoliation to maximize yield potential and lint quality.

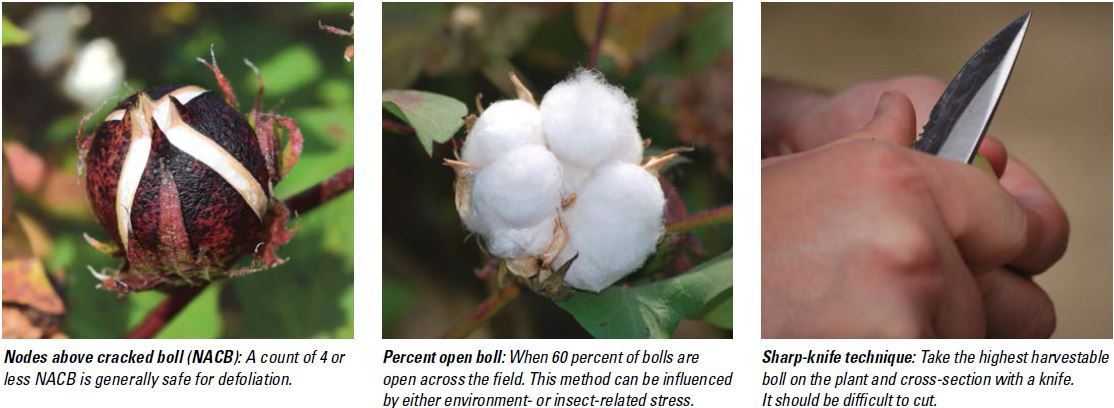

There are several ways to determine the best time to apply defoliants. To check the timing, growers will need to visually inspect cotton plants.

Use the above methods together to confirm if a field is ready for defoliation. Remember to check each field, as maturity will fluctuate based on varieties and agronomic conditions.

Assessing the environment and crop condition is the next step. Weather conditions at the time of defoliation, and three to five days following, have significant impact on cotton response.

The third step in the TEAM approach is selecting the most effective application method for defoliants. In cutout or short-statured cotton, a single application typically should be sufficient to remove leaves and open bolls. Rank cotton may require a two-shot approach: one application to open the canopy, followed by a second application to finish defoliation and open bolls.

With either approach, it’s important to remember that defoliants work on contact, so adequate canopy coverage is essential for performance. Use the following tips to ensure proper coverage:

The last step of this process is to pick which harvest aid material would be best for the selected cotton field. Because field conditions are highly variable, work with your local team of PhytoGen field agronomists, consultants, retailers and Extension to determine the right defoliant for your situation.

Types of harvest aids:

Once a harvest aid is selected, good field planning will help you stagger applications for a successful harvest. Use these guidelines to aid in field planning and defoliation timing:

As you follow the TEAM approach outlined above, our PhytoGen experts are available to help you make the right decisions to drive cotton harvest success. To connect with your local PhytoGen field team member visit PhytoGen.com/Team.

Find information on yield and more in the PhytoGen Cottonseed Agronomy Library.